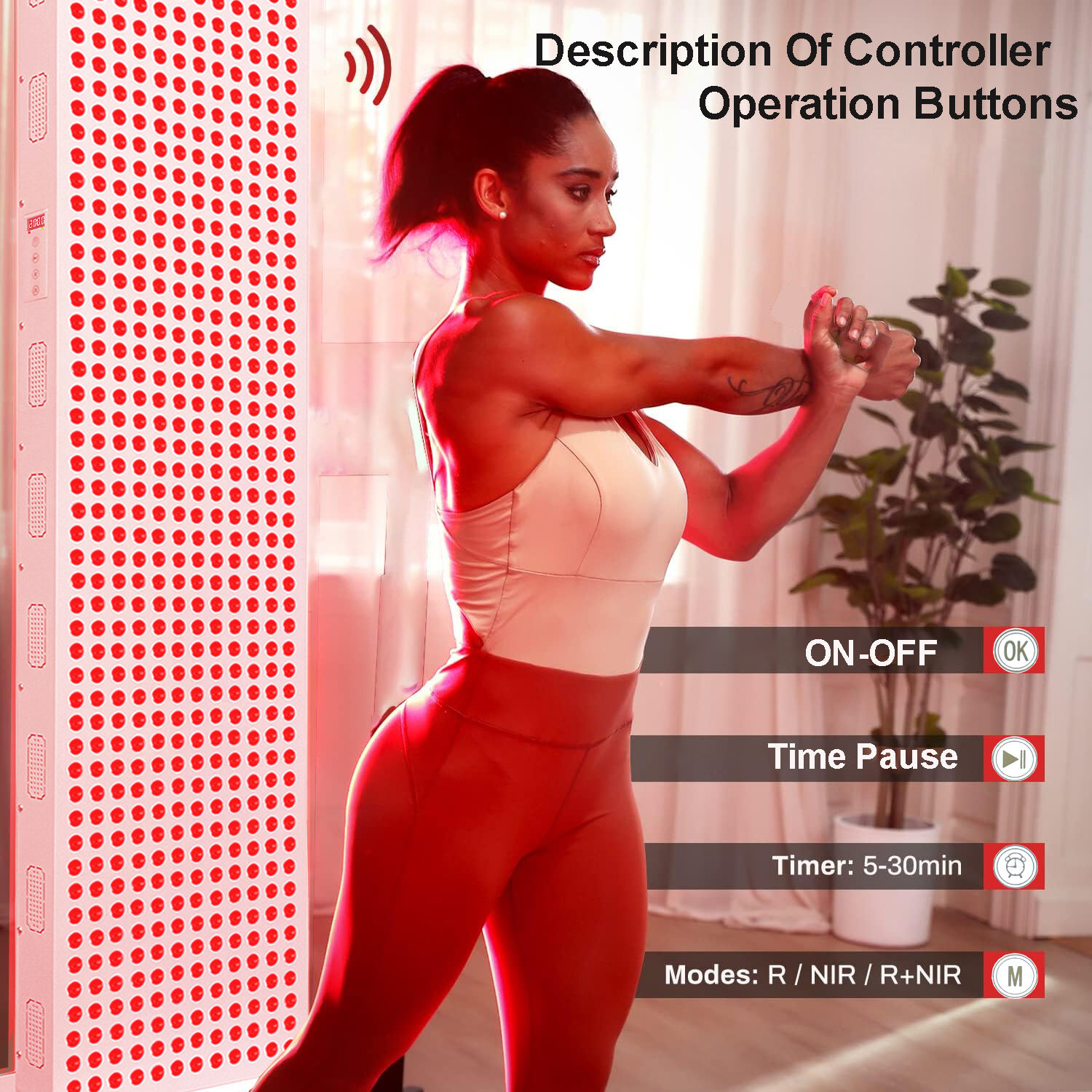

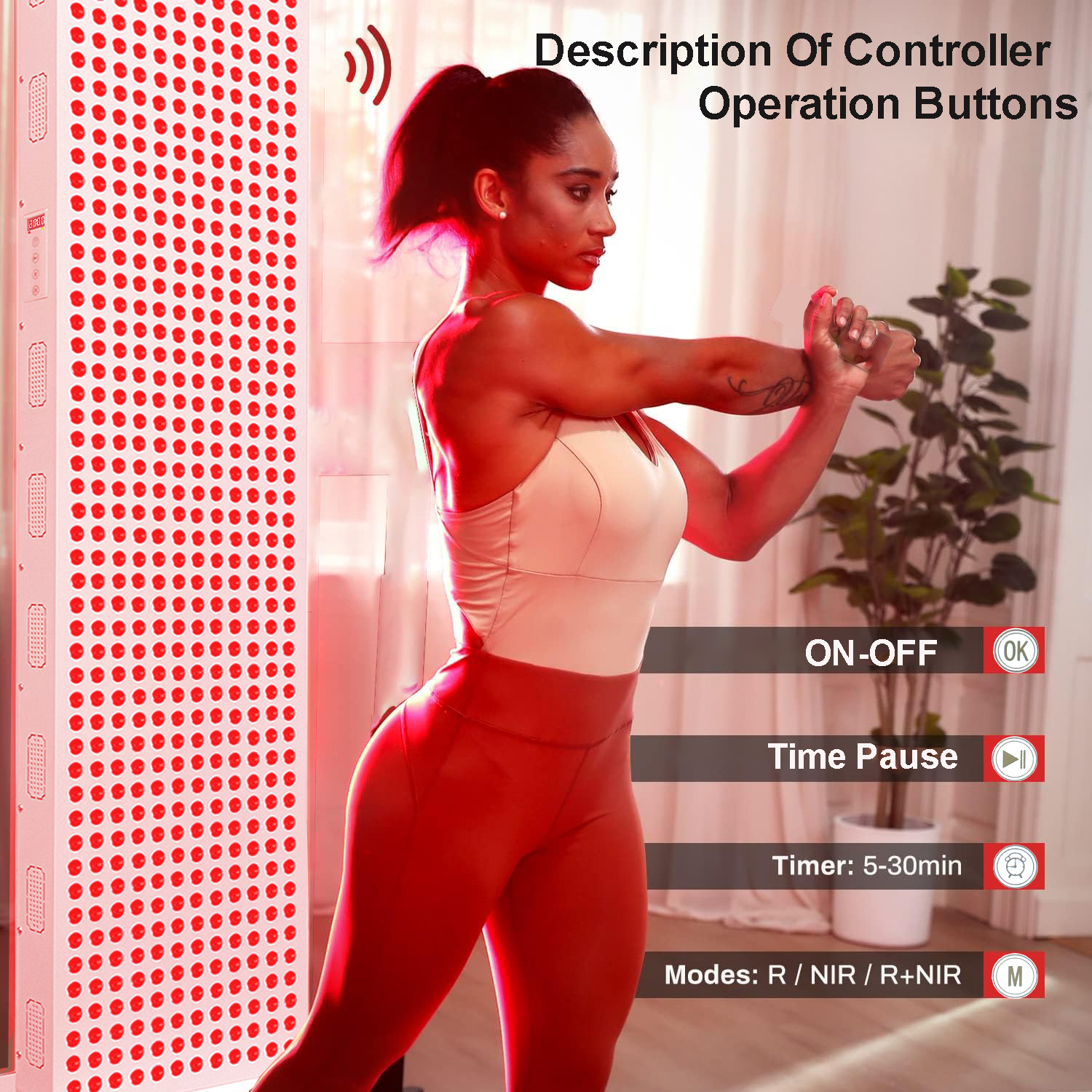

Panel de Terapia con Luz Roja JUNNEELED | Mejores Paneles Corporales de 630nm y 1000W en Venta

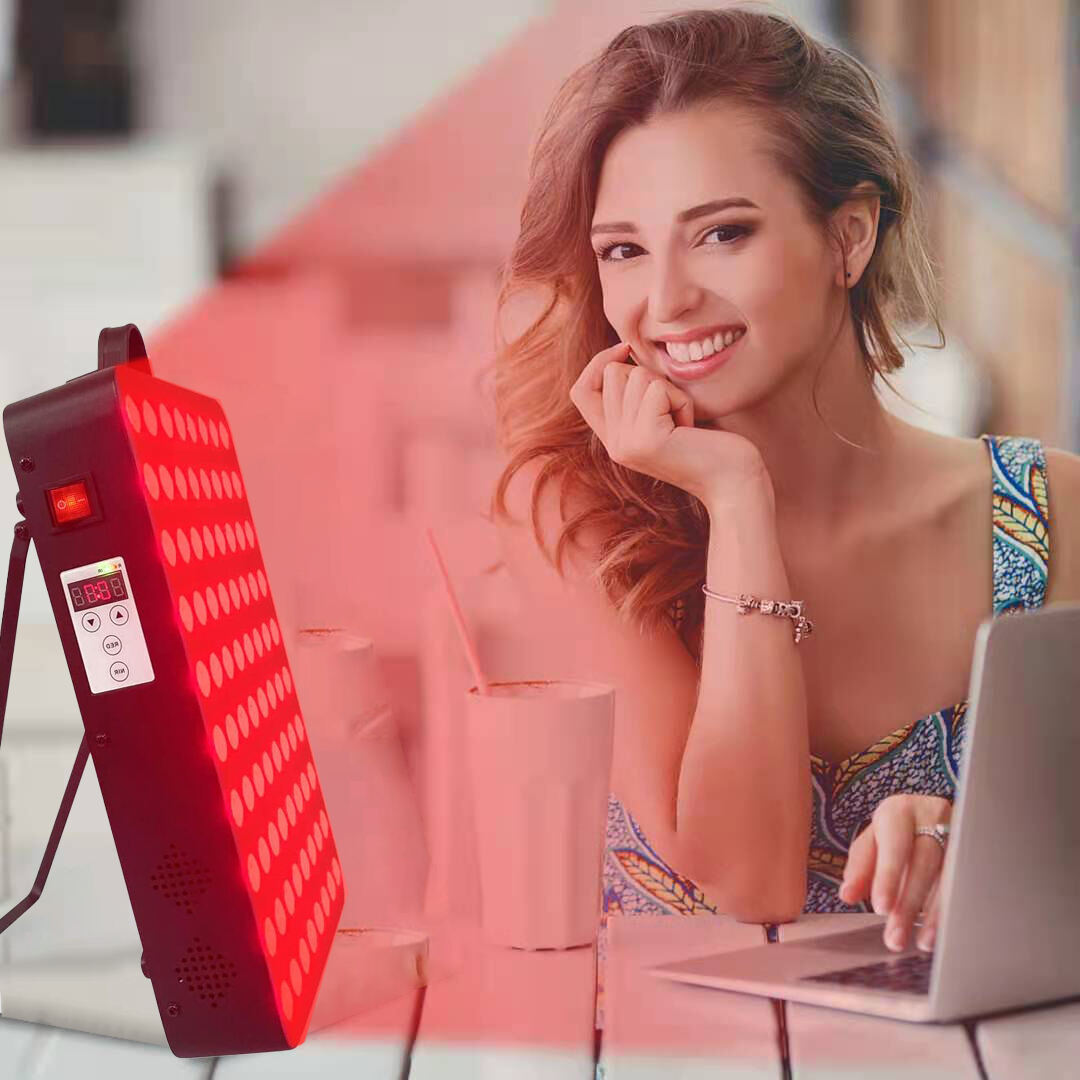

Descubre el panel de terapia con luz roja de JUNNEELED, diseñado para uso profesional y en el hogar. Nuestro panel de terapia con luz roja de 1000W ofrece luz de longitud de onda clínica de 630nm para la regeneración del cuerpo entero, recuperación muscular y reparación de la piel. Con intensidad personalizable y opción de soporte móvil, puedes experimentar terapia con luz roja dirigida donde la necesites. Compra al por mayor paquetes de paneles de terapia con luz LED roja y compara precios de paneles de terapia con luz roja para obtener un valor incomparable.

Obtener Cotización